Harrison M300 Lather CNC Attachment (2023)

I've wanted a CNC lathe for a long time but space makes it prohibitive.

After stumbling across a video on YouTube by Kerkko Nenähaima and his CNC attachment, I took inspiration and decided to build my own version.

There were a number of feature I didn't need so I set about making my own design with a somewhat simplified construction with less machining, parts sourced from the UK, and the use of standard material stock sizes.

I have a bridgeport mill I converted to CNC so already had a computer and mpg pendant controller, so I didn't need to build in the controls on the compound slide.

This also has the benefit of a clear view, nothing in the way of access to the chuck for measuring etc., and a clear path for swarf removal.

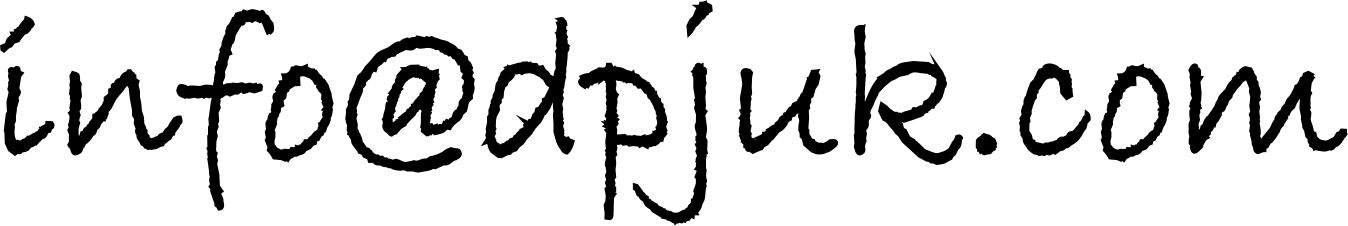

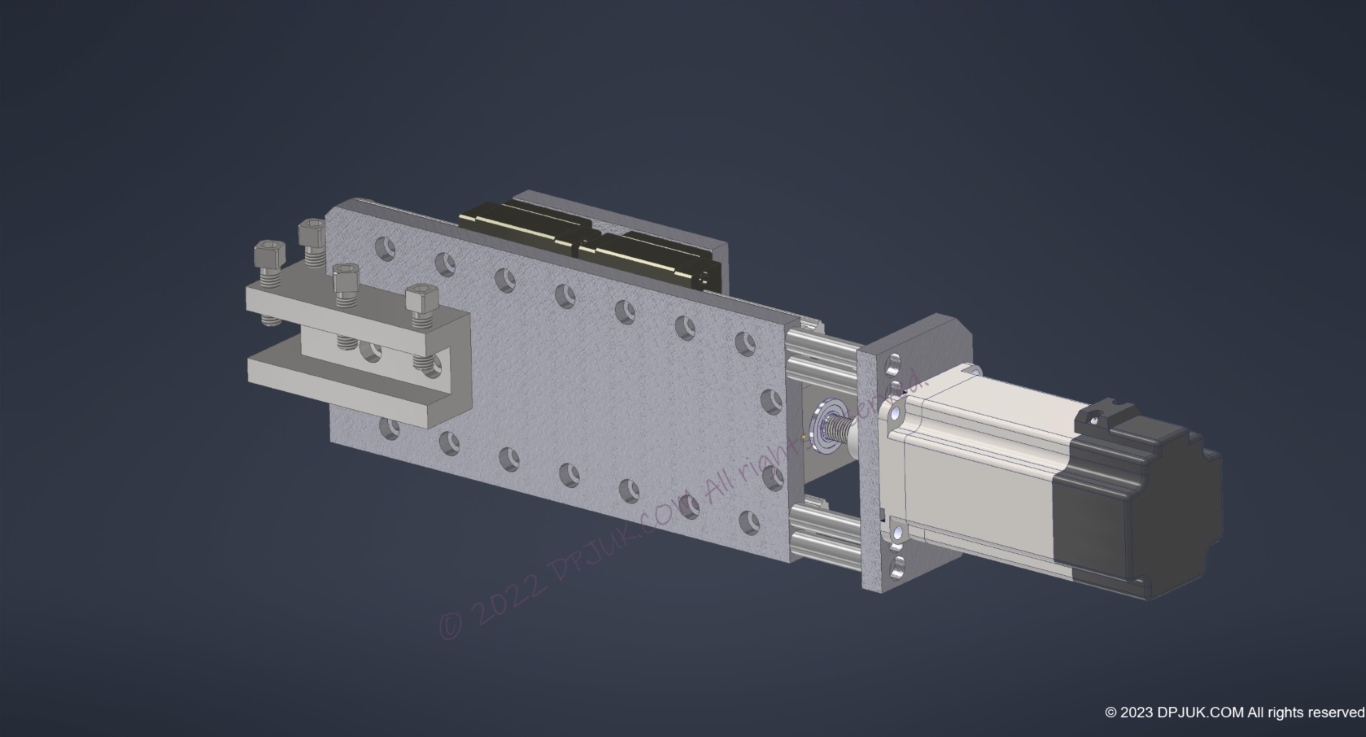

I started by modeling the whole assembly in 3D CAD, and produced production drawings. The design is done to minimise the machining required and using standard stock size materials as much as possible.

Having now been in use for several months I can say it's been a great addition and probably one of the most useful builds.

I've not only machined softer non-ferous materials, but also alloy steels such as EN19T without issue, providing you don't go mad with cutting depth and feed rate.

There's other advantages with a tool post mounted X-Axis in that you can easily mix the use of CNC and manual machining. You can retract the whole carriage away from the chuck for polishing, measuring, material/part change etc. and then simply move the carriage back into position with the DRO set to zero.

Although the compound slide only has about 90mm movement you can also machine longer lengths in stages by splitting the CNC program up into segments and moving the carriage along.

.jpg)

.jpg)

Cutting the srtock to size

.jpg)

.jpg)

Main plate finished and extra screw holes drilled on the rails

.jpg)

Leadscrew machined and threaded

.jpg)

Parts finished ready for assembly

.jpg)

.jpg)

It all just screws together.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

P40-5M-25F pulley machined to fit compound slide.

.jpg)

.jpg)

.jpg)

While I had the compound slide off I machined a pocket in the top so I can add either a ballscrew or a means to take the backlash out of the standard acme screw.

.jpg)

The compound bracket was made from some steel plate I had on the shelf. No drawings made for this.

.jpg)

Electronics cabinet with drives and power supplies installed.

.jpg)

.jpg)

Micro switches fitted for homing and limits.

.jpg)

.jpg)